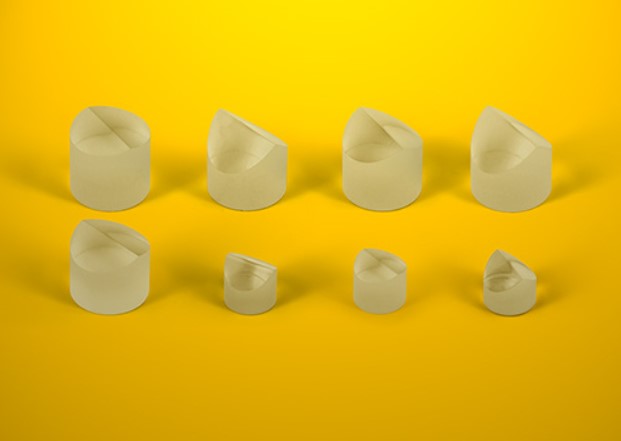

The Powell Lens is similar in appearance to a round prism with a curved roof line. They are also known as laser line generator lens. As opposed to standard cylindrical lenses, Powell Lens can create fine laser lines which are straight and uniform. While cylindrical lenses produce diverging laser lines with Gaussian intensity profiles, Powell Lens produce fine lines by fanning collimated, parallel, well aligned and corresponding beams in one dimension only. Powell Lens are available at fan angles of 30°, 45°, 60°, or 75°.

Powell Lens generates a laser line by stretching a narrow laser beam into a uniformly illuminated straight line. It is a revolution in the field of laser and lenses as it amps up the simple cylinder lenses’ performance phenomenally. The rounded roof of Powell Lens is a complex two-dimensional aspheric curve which produces a significant quantity of spherical aberration. This special light has an increased amount of light at the line’s ends whereas the central area is not so well illuminated. The redistribution of light takes place along the line. This fine uniform line is used in a wide range of machine vision applications from various industries and sectors. From high-tech bio-medical applications to a candy production- Powell Lens are equally popular and effective because of their splendid beam generation. In this article we have discussed five reasons and benefits to use Powell Lens. Let’s take a look.

Benefits of using Powell Lens

Compared to chamber lens, the Powell Lens is a marvelous improvement in the field of line generation. The biggest limitation and drawback for a chamber lens is a non-uniform poorly lit up line. Due to its adjusted rooftop, the Powell Lens is nothing but a complex two-dimensional aspheric bend that generates a light beam with altered characteristics. This beam, on its way, is more illuminating at the ends whereas in its focal territory, the beam is not so visible. Some of the advantages which Powell Lens offer are given here:

1. Fan Angle

The refractive list of the glass and the rooftop edge rely on the width of the Powell Lens fan edge. If the rooftop is extreme, and the refractive record is also on the higher side then the fan edge will be more extensive and more prominent to differentiate the line for a given projection separation.

2. Laser Beam Size

Laser line thickness depends on the episode laser bars measurement at a specific projection separation. An aligned and uniform laser diode comes with a round bar cross segment allowing a solitary diode module. The solitary diode can have a little as well as a hefty line ability- which completely depends on your preference and requirements for the line.

3. Line Uniformity

Powell Lens allow better line uniformity as just like the nature of the lens’s aspheric surface, the performance is strictly dependant on the episode laser bar’s attributes. To ensure consistency and uniformity, the Powell Lens must coordinate with the laser module’s specific shaft attributes at the time of laser line accomplishment.

4. Mounting the Powell Lens

It is of paramount significance to mount the Powell Lens with caution to ensure that there is no section of the veering bar radiating from the lens’s Plano leave face. As a result of the scattering beam from the Powell Lens, line consistency can ensured by adjusting or cutting a noticeable fan edge light bar near the leave surface.

5. Straight Laser Line Lens and Bore sight

Just like the laser module decides its accuracy, the assembling nature of Powell Lens decides its line straightness and bore sight deviation. In order to ensure the rooftop’s oppositeness to the occurrence light so that line rise and fall can be initiated, it is significant to plan and fabricate the Powell Lens cell and its interface with the laser.

Final Words

For highly quality services related to Powell Lens, and laser line lens, get in touch with us.